Stop Slab Tip-Overs Before They Start

Featuring the patented RockLock™ Safety Arm System

Safe Stone Handling builds RockLock™ powered systems that reduce over-center tipping risk during warehouse staging, transport, and container unloading.

See how RockLock™ prevents over-center tipping during routine movement.

Download One-Pagers

Not sure where to start? Most teams begin with Overhead Universal RockLock™ or Knockdown Safe A-Frame

Start With the Right System

Choose the system that matches your setup, your workflow, and where slabs move

through your operation, from receiving to transport to storage.

Overhead Universal RockLock™

Overhead Universal RockLock™

Best for:

Pickup trucks, utility trailers, and warehouse setups with an existing A-frame.

Requires an existing A-frame.

Key benefits:

Works with existing A-frames to help reduce over-center tipping risk

Fast to deploy for daily movement, staging, and handling

Helps create a more repeatable safety process without relying on perfect setup conditions

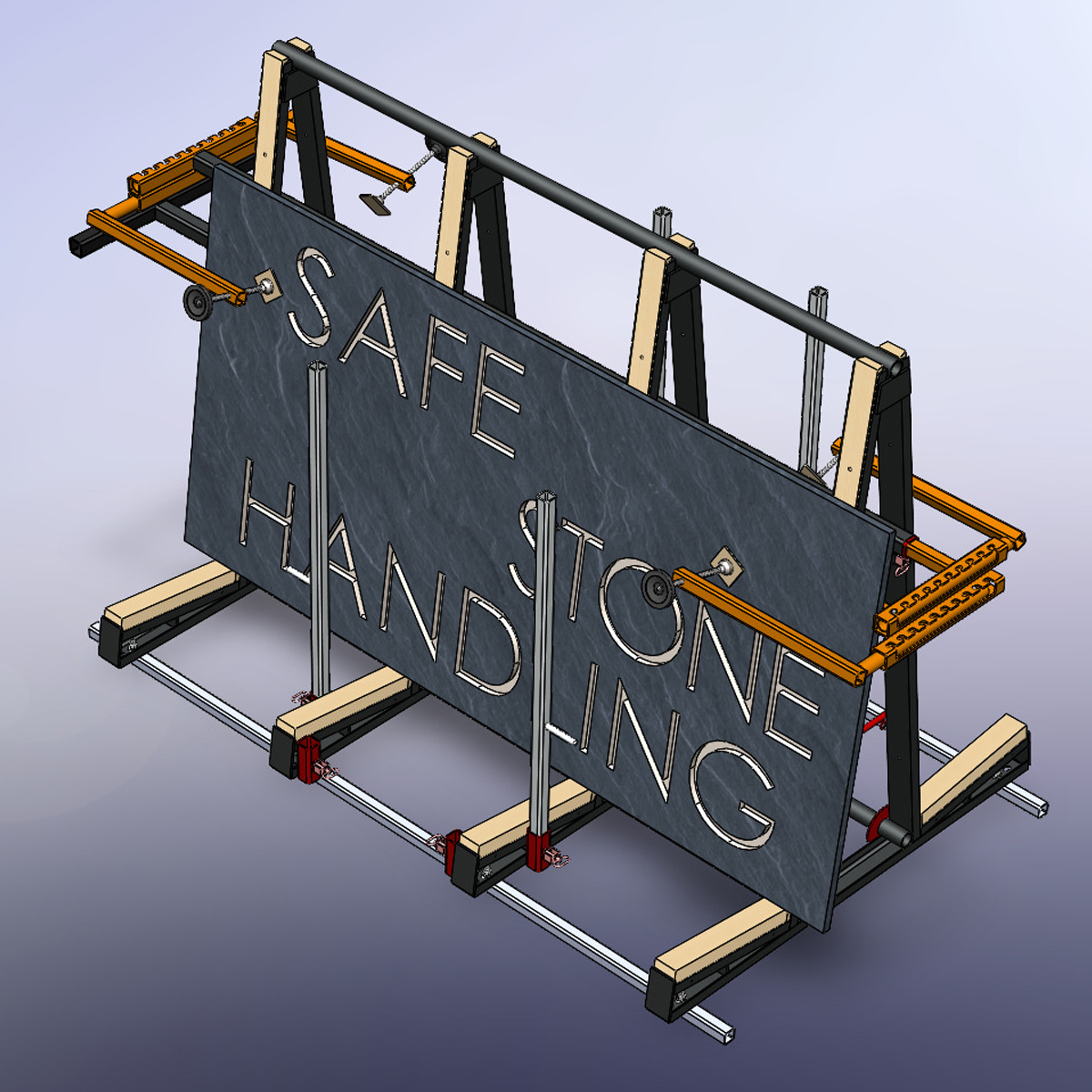

Universal Knockdown SAFE A-Frame System

Overhead Universal RockLock™

Best for:

Operations that need a complete A-frame system shipped as a kit.

Includes a knockdown A-frame kit.

Key benefits:

Ships as a knockdown frame kit assembled on-site

Mobile and warehouse configurations to match your operation

Ideal when you need standardized frames for safer staging and storage workflows

Truck Safe Strapless

A-Frame

Truck Safe Strapless A-Frame

Best for:

Flatbed transport where shifting and strap failure increase risk.

Key benefits:

Strapless mechanical compression system designed to reduce slab shifting

Built for stability under vibration, starts/stops, and road movement

Engineered A-frame approach for demanding hauling environments

Strapless mechanical compression system designed to reduce slab shifting

Built for stability under vibration, starts/stops, and road movement

Engineered A-frame approach for demanding hauling environments

Container Bundle Stabilization Mechanism

Container Bundle Stabilization Mechanism

Best for:

Unloading stone bundles from shipping containers at your facility.

Key benefits:

Stabilizes bundles before off-loading to reduce sudden tip-over events

Supports a safer unloading sequence from container to staging

Helps reduce severe incident risk during receiving and first movement

Not sure which fits? Tell us what you’re moving and how you’re set up.

Safety Solutions by Workflow Stage

Choose where risk shows up in your operation, then jump to the systems built for that stage.

Warehouse & Yard Storage

Overhead Universal RockLock™

Everyday staging and repositioning can trigger over-center tipping risk if slabs aren’t stabilized consistently.

Transport & Delivery

Overhead Universal RockLock™

Vibration, shifting, and sudden stops can turn routine hauling into a tip-over event without the right system.

Container Unloading & Receiving

Overhead Universal RockLock™

Bundles can shift inside the container. The first movement during unloading is often when tipping risk spikes.

Not sure where your biggest risk is? Tell us your workflow and your current setup.

RockLock™: The Patented Slab-Securing Technology Behind Our Safety Systems

RockLock™ helps reduce over-center tipping risk by stabilizing slabs during key stages of handling, from staging and transport to container receiving.

How RockLock™ helps

Stabilizes slabs to reduce over-center tipping risk

Creates repeatable process control (less reliance on inconsistent tie-down habits)

Integrates into multiple systems (existing-frame setups and complete frame kits)

Built for real-world handling during movement, staging, and first unload

Why Safety Directors and Executives Are Switching to Safe Stone

Stone slabs can tip when they move past over-center, especially during routine staging, transport, and first movement during unloading. Safe Stone Handling systems are built to reduce that risk with a repeatable process that supports safer operations and stronger incident defensibility.

✅ Reduce severe tip-over risk during critical handling stages

✅ Reduce slab damage and downtime caused by preventable incidents

✅ Support a more consistent safety process across teams and sites

✅ Improve defensibility after incidents with engineered controls vs improvised methods

Built From Real-World Slab Handling Experience

Louwrens Mulder

Stone industry professional.

Creator of the patented RockLock™ safety mechanism.

RockLock™ was engineered to help teams reduce over-center tip-over risk with a repeatable, real-world slab-handling process.

“No one should have to risk their life to deliver or install a countertop or stone slab.”

— Louwrens Mulder

See RockLock™ Systems in Action

Patented. Proudly Engineered in the USA.

Short demos for staging, transport, and receiving.

Knockdown SAFE A-Frame System

What you’ll see: Knockdown frame kit setup and stabilized staging/storage workflow.

Truck Safe Strapless A-Frame

What you’ll see: Strapless transport stability during loading and road movement.

Container Bundle Stabilization Mechanism

What you’ll see: Works with existing A-frames for daily handling and staging.

One Mistake Can Cost Lives and Trigger Serious Liability

Stone slabs can tip when they move over-center, especially during routine staging, transport, and first movement during unloading. When handling relies on improvised supports or inconsistent tie-down practices, the risk increases, and the consequences can include injury exposure, product loss, downtime, and major liability.

Engineered controls help reduce that risk by creating a repeatable process that’s less dependent on perfect conditions.

“This is why safety systems must be engineered, not improvised.”

Examples of reported incidents in the industry:

Two workers crushed at Stone Warehouse of Michigan.

Huntsville Granite cited for fatal slab accident.

Semi-truck granite spill on I-24 causes massive delays.

Survivor crushed by 10,000 lb slab: 110 titanium screws hold his face together.

Content Hub

Stay connected and get practical safety insights, updates, and real-world demos.

Rock Solid Safety Blog

Real-world risk scenarios, safer workflow tips, and product updates.

Connect on LinkedIn

Industry updates for safety leaders, distributors, and fabricators.

FAQS

Will your systems work with my existing A-frames, trucks, or trailers?

Yes! Our systems are designed for easy “bolt-on” and HD Tie Down Chain Binders installation to fit most truck beds, semi-trailers, and even smaller transport equipment.

How does this help reduce tip-over risk and liability exposure?

Our engineered systems dramatically reduce the risk of slab falls, which are a leading cause of injuries and fatalities in the industry. Investing in safer equipment protects your people, reduces worker’s compensation claims, and protects your bottom line.

Do I need an A-frame already?

Some systems work with existing A-frames (like Overhead Universal RockLock™). If you don’t have a suitable frame, the Knockdown SAFE A-Frame System includes a complete frame kit.

Which system is strapless?

The Truck Safe Strapless A-Frame is designed as a strapless transport system. Other setups may still use tie-downs depending on configuration and application.