Slabs Don’t Fall—Until They Do.

Warehouses are full of hidden risks. One unsecured slab can destroy a life, a reputation, or your business. The RockLock™ Warehouse Slab Safety System stops it before it starts by attaching to your existing A-Frames!

Easy Setup to Upgrade your Existing A-Frames!

The Danger Is Real—And It’s Underestimated Every Day.

In warehouses and slab yards, slabs weighing hundreds—sometimes thousands—of pounds are often stored on fixed A-frames with no restraint system. Customers walk by them, workers move them, and hope nothing goes wrong. But hope isn't a safety strategy.

Over a dozen OSHA-reported fatalities in the last 5 years due to falling slabs.

Example: Two workers crushed by slabs in Michigan during unloading.

Injuries lead to lawsuits, OSHA fines, damaged products, and destroyed morale.

Two workers crushed at Stone Warehouse of Michigan.

Huntsville Granite cited for fatal slab accident.

The Solution – RockLock™ Warehouse Slab Safety System

Bolt-On Safety. Built to Save Lives.

The RockLock™ Warehouse Slab Safety System transforms ordinary A-frames into secure, safe, slab storage units.

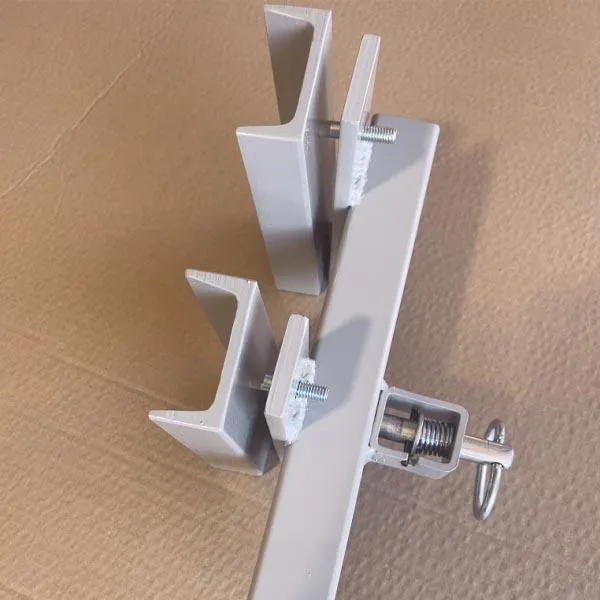

✅ Patented RockLock™ Arm System – Prevents slab tipping during loading, unloading, and storage.

✅ Universal Fit – Bolts onto most fixed A-frames (no welding or modification required).

✅ High Capacity – Secures up to 15 slabs per side.

✅ Quick-Adjust Arms – Accommodates slabs of various sizes.

✅ Tool-Free Engagement – Fast locking/unlocking streamlines workflow.

✅ Proven Results – Trusted by fabricators, distributors, and shop owners nationwide.

How RockLock™ Keeps Your Slabs—and Your Team—Safe

Install: Bolt onto each side of your A-frame in minutes—no welding required.

Load: Slabs are placed with a forklift or crane. Lock arms engage and hold slabs in place.

Secure: Lock arms adjust vertically and horizontally for precise fit. Slabs remain fully restrained—even during slab changes.

Built to Help You Meet—and Exceed—OSHA & ANSI Standards

Mitigates risk of serious injury or death

Helps reduce liability and insurance premiums

Demonstrates your company’s safety-first culture

Protects against lawsuits, fines, and bad press

Specs & Details

Key Features

RockLock™ Adjustable Lock Arms

Engineered to securely hold stone slabs in place during material handling operations—greatly reducing the risk of tipping accidents.High Capacity

Secures up to 15 slabs per side, suitable for granite, quartz, marble, and porcelain slabs.Universal Bolt-On Fit

Designed for easy installation on most standard fixed A-frames already in use in warehouses—no welding or frame modification needed.Fast Adjustability

Lock arms are vertically and horizontally adjustable to accommodate slabs of varying height and thickness—ideal for high-turnover storage.Low-Profile Design

Operates above the slab height to avoid interference with slab access, maximizing warehouse space without compromising safety.Manual Quick-Lock Mechanism

Lock arms feature intuitive quick-adjust hardware—vertically and horizontally adjustable—allowing fast and secure locking or unlocking during slab loading and unloading. Designed to streamline operations when adding or removing slabs from an A-frame, while maintaining maximum safety.Use Cases

Perfect for safe loading, unloading, and temporary storage of stone slabs with indoor and outdoor warehouse/storage environments.

Specifications

Maximum Capacity: 15 slabs per side

Installation: Bolt-on system; compatible with most standard fixed warehouse A-frames

Material: Heavy-duty steel

Finish: Industrial-grade powder coating for enhanced durability and corrosion resistance

Adjustable Height: Up to 2 feet

Unit Weight: 60 lbs (each)

What Industry Pros Are Saying

“We added RockLock™ to every A-frame after a close call—and I sleep better because of it.”

— James R., Warehouse Manager, Atlanta

“It’s simple, fast, and saves us thousands in damage and downtime.”

— Laura T., Fabricator, Illinois

FAQS

What makes Safe Stone Handling’s equipment different?

Our patented RockLock™ Safety Arm System and Vertical Support Posts are engineered to prevent slabs from tipping or falling during loading, unloading, and transport. Unlike traditional A-frames, our products are designed to survive sudden stops and collisions, protecting your team and your cargo.

Who is this equipment designed for?

Safe Stone Handling solutions are made for slab importers, wholesalers, distributors, and fabricators—any company that transports, warehouses, or installs large stone slabs.

Can your A-frame systems fit my existing trucks or trailers?

Yes! Our systems are designed for easy “bolt-on” and HD Tie Down Chain Binders installation to fit most truck beds, semi-trailers, and even smaller transport equipment.

Will this really reduce injuries and insurance claims?

Absolutely. Our engineered systems dramatically reduce the risk of slab falls, which are a leading cause of injuries and fatalities in the industry. Investing in safer equipment protects your people, reduces worker’s compensation claims, and protects your bottom line.

Is this equipment expensive?

While there’s a premium for high-quality, U.S.-made equipment, the cost is small compared to the savings from fewer injuries, reduced product damage, and avoiding legal liabilities.

How soon can I get Safe Stone Handling equipment?

Production capacity is available now, and limited quantities are ready for immediate shipment. Contact us today to check availability.

Can I talk to someone or schedule a consultation?

Yes! You can:

📅 Book a Free Safety Assessment

💬 Chat with us live or use our AI Safety Bot